SENSING AND CONNECTIVITY

Today’s products are considered “smart” because they can sense their environment, communicate with other electronics, and enable faster, more-informed decisions and outcomes. For example, modern cars are equipped with a host of sensing and communication technologies to make drivers safer, better connected and more informed. The sheer amount of smart functionality in cars today is staggering. Unlike previous generations of automotive engineers, engineers designing today’s cars need to consider electromagnetic interference, signal integrity, uninterrupted connectivity and other complex issues that may affect electronic performance. Simulation provides a means of maximizing reliability and ensuring a robust design from the earliest stages of product development.

RELIABILITY AND SAFETY

While the IoT is driving enormous revenues, those revenues can’t be outweighed by the cost of maintenance, repair, warranty charges or lack of uptake by the market. In addition, many products — such as those in the automotive, aerospace and healthcare industries — operate in safety- critical environments. Because lives are at stake, these products need to meet the highest standards for reliability and safety. An often-overlooked, yet mission-critical, aspect of the IoT is the embedded control and display software needed to operate the integrated mechatronic systems that guide connected cars and aircraft. Validating the tens of millions of lines of safety-critical embedded software code that underlie these systems is essential. Simulation and modeling enable the fast, automated production of flawless code that is needed whenever human safety is involved.

INTEGRATION

As the complexity of smart, connected products has increased over time, engineers have broken down the design process into smaller pieces to make it more manageable. While a component-level, bottom-up design methodology allows for very thorough verification of pieces and parts, significant late-stage design issues can arise when components are actually assembled to create a system. Finding system-level flaws late in the development cycle can lead to over-design, cost overruns and ill-considered design trade-offs as engineers scramble to meet product launch deadlines.

DURABILITY

While tiny and often unseen, trillions of sensors and microprocessors form the backbone of the IoT. These hardworking electronics collect and share useful information 24 hours a day, seven days a week. They need to perform reliably not just in optimal conditions, but must also withstand the rigors of harsh, unpredictable environments. Simulation plays an essential role in bringing these innovations to market with a promise of reliability. While not all products need to endure extreme conditions, every product must be verified for durability. Anyone who has dropped a smartphone understands the rigors of everyday usage.

SMART PRODUCTS REQUIRE COLLABORATIVE DESIGN

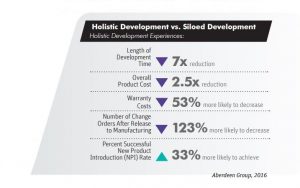

Independent research has shown that smart product design requires an increase in communication and collaboration among functional engineering teams. A product designed without collaboration can lead to integration issues, especially when subsystems are built and over-designed as each team adds its own safety margins. Launch delays, reliability issues and cost overruns are other risks.

Engineering simulation is an important vehicle for fostering collaboration. Today, best-in-class companies use a consolidated simulation platform to analyze component- and system-level behavior, as well as subsystem interactions, before building physical prototypes. This ability to analyze multiple alternatives enables designs to be optimized for cost, quality or performance.