The Inernet of Things (IoT) is clearly an exciting business opportunity for large and small companies. Yet success in the IoT economy depends on the ability of companies to constantly reinvent their offerings. Increasingly, product development and engineering teams need to address critical challenges related to communication system design, sensor design and product reliability to out-innovate the competition.

SMART DESIGN VIA SIMULATION

The multiphysics, multidomain capabilities of simulation software portfolio are especially critical in engineering today’s smart, connected products. Because these products have complex functionality, smart product development teams demand an extremely high level of reliability, precision, robustness and innovation. At the same time, these teams face enormous pressures to keep costs low and accelerate launches. To achieve these goals, companies can neither design in silos nor rely on traditional build-and test methods.

The multiphysics, multidomain capabilities of simulation software portfolio are especially critical in engineering today’s smart, connected products. Because these products have complex functionality, smart product development teams demand an extremely high level of reliability, precision, robustness and innovation. At the same time, these teams face enormous pressures to keep costs low and accelerate launches. To achieve these goals, companies can neither design in silos nor rely on traditional build-and test methods.

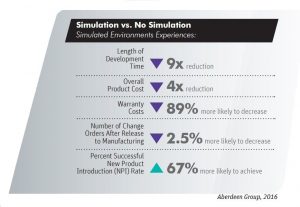

Not only is simulation a competitive requirement today, but it has significantly leveled the playing field, enabling smaller companies to compete with established market leaders.

ENGINEERING THE IOT

FIVE KEY CHALLENGES

While every smart product has its own design challenges, the exponential growth of the Internet of Things means that some common design requirements are emerging. For example, each new generation of smart products typically must be smaller, lighter in weight and more power-efficient than the previous generation.

There are five key engineering challenges created by the rise of the IoT, and we explore them below.. The sheer size of the IoT opportunity is creating new competitors for many established market leaders.

SIZE, WEIGHT, POWER AND COOLING (SWAP-C)

Whether designing planes, cars or smartphones, engineers typically need to optimize IoT products for size, weight, power and cooling — a set of design requirements popularly known as SWAP-C. As consumers demand greater functionality, including pervasive connectivity and sensing, engineers are forced to add more electronic components. This high density of electronics brings new challenges in terms of product size, weight, energy demand and thermal build-up. Engineers must manage all these components in a constrained space while optimizing performance. This means relying on simulation to make design trade-offs quickly and cost-efficiently.