Energy efficiency is the need of the hour and low-power-consuming microcontrollers (MCUs) are the foundation for efficient devices. The number of embedded devices running on battery power, or in other words parasitic power, continues to grow. Today, the design portability equates product profitability and low power is one of the main requirements of any design.

IoT driving power-efficient MCUs

Power-efficient MCUs are the rage these days and the Internet of Things (IoT) is what is driving them. For example, the 32-bit ARM Cortex-M0+ based Freedom Platform of MCUs is one such family of MCUs drawing currents near single-digit micro-ampere levels. Guru Ganesan, managing director, ARM India, says, “The ARM Cortex-M0+ processor behind this Freedom family of MCUs has been engineered with a two-stage pipeline for a power-efficient operation, specifically keeping IoT in mind.”

Designers are constantly demanding MCUs which use less power and have the capacity to support multiple actions simultaneously. The power-efficient MCU gives a designer an edge to work over various embedded applications and get a wide range of advantages like low-power libraries, gate level optimisation and power gating. Sanjay Gupta, R&D director, Automotive & Industrial MCU Group, India Design Center, Freescale Semiconductor India Pvt Ltd, says, “Performance-per-watt levels have evolved in many embedded applications to enable power-efficient designs, which help the end user to conserve energy.” He adds, “In fact, considering the looming power crisis, regulatory authorities have made it mandatory for consumer appliance companies to upgrade their products and display the energy-efficiency ratings, enabling the consumer to make smart choices.”

Low-power-consuming MCUs are certainly new to the market and a lot of innovation is being done in this space to support and help the engineers to develop smarter products and solutions.

Latest functionalities in MCUs

Today, most of the MCUs not only have tiny form factors and in-built wireless capabilities, their development boards also support ZigBee, Bluetooth or Wi-Fi capabilities—all capable of sitting on your fingertip. Ganesan says, “For example, the ARM Cortex-M0 based nRF51822-mkit from Nordic Semiconductor has a Bluetooth Low Energy (BLE 4.0) on the same chip on which the ARM Cortex-M0 sits.” Some other examples of development boards with such ARM based MCUs are MetaWear from Mbient Lab Inc. and RFDuino from RFDuino.com.

He adds, “Because of the tiny MCU form factors, these development boards are in turn tiny as well. Yet another similar platform is the ARM Cortex-M3 based spark core with an on-board Wi-Fi unit.” MCUs are additionally being enhanced with high-end digital signal processing (DSP) capabilities to handle image-processing, voice and similar other signal processing requirements as well. Cortex-M7 is an example.

Freescale’s low-power MCU portfolio extends from ultra-low-cost, small-footprint eight-bit MCUs with one kilobyte (kB) of Flash to high-performance 32-bit MCUs with up to 128kB of Flash. Gupta informs, “Low-power features include clock gating, multiple low-power operating modes and a 32kHz oscillator that consumes less than one micro-ampere.”

Texas Instruments’ (TI) CC430 family is another example of a wireless MCU that provides tight integration between the MCU core, peripherals, software and a sub-GHz radio frequency transceiver. TI’s CC2541 is another power-optimised wireless MCU example, which enables BLE and proprietary 2.4GHz network nodes to be built with low total bill of material costs.

MCUs with growing interfaces

MCUs today have a lot of interfaces that enable hooking up various kinds of sensors and actuators. The interfaces include general-purpose input/output (GPIO), analogue in, analogue out, pulse width modulation (PWM), universal serial bus (USB) host and device, inter-integrated circuit (I2C), serial peripheral interface (SPI), universal asynchronous receiver/transmitter (UART), RS232, built-in analogue-to-digital converter (ADC) and built-in digital-to-analogue converter (DAC), to name a few. These interfaces, along with currents in the near single-digit micro-amperes, make MCUs even more ideal for IoT. Ganesan says, “There is a lot of developer as well as application migration from eight and 16-bit MCUs to 32-bit ones today.” He explains, “The chief reason being that typical modern-day or IoT type of applications require more memory (determined by the address bus size), as well as larger data buses, for quicker and more efficient operation from a lay-person’s standpoint.”

MCUs also offer high-resolution ADC to 24-bit sigma delta ADC, high-resolution DAC, real-time clock (RTC) and liquid crystal display (LCD) controllers. Some companies also offer real-time operating system (OS) free with 32-bit MCUs.

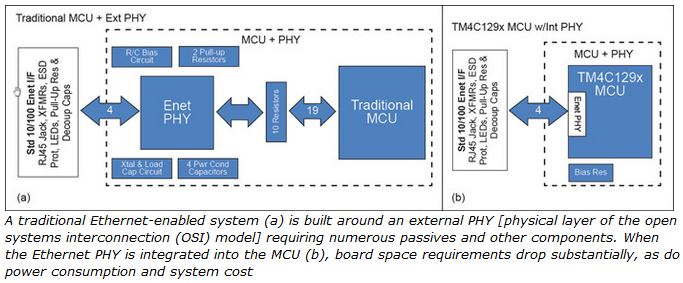

PHY integration reduces board space, power consumption and cost

The value of the IoT comes from its interconnectedness. In many cases, connectivity substantially enhances the utility, serviceability and versatility of embedded systems. An IoT system must often be able to connect in two directions: down to its sources of data such as sensors or other IoT devices, as well as up into the cloud to a data aggregator or centralised control point, informs Joe Folkens, product marketing engineer, Texas Instruments, in his whitepaper. He points out, “Connecting to data sources requires support for a wide range of machine-to-machine (M2M) protocols running over interfaces such as I2C, SPI or UART. Connecting to the cloud through the Internet requires an IP based interface, typically Ethernet for wired connectivity and Wi-Fi for wireless applications.”

The ubiquity of 10/100 Ethernet makes it a compelling option when secure connectivity to a wired product line is needed. The challenge for developers is to implement this connectivity at the lowest cost and power, without compromising performance or reliability.

Traditionally, the Ethernet MAC has been integrated onto MCUs to reduce cost and design complexity. The Ethernet PHY, on the other hand, has been implemented as a separate component due to analogue integration challenges. Many applications, however, could also benefit from integrating the PHY as well.

An example of MCUs with integrated MAC/PHY is TI’s TM4C129x MCU family. It provides an effective solution for connecting systems to the cloud so they can take full advantage of the capabilities enabled by the IoT.

How design engineers are benefited

With onboard or on-chip BLE, ZigBee or Wi-Fi capabilities, and the various interfaces for hooking up sensors, these tiny development boards can be used for both prototyping and production, drastically reducing the time-to-market which the production versions take. Ganesan says, “They help designers to focus more of their energy and time on the real challenges at hand and the systems that can overcome these challenges, than worry about sourcing individual hardware components, manufacturing boards with smaller form factors and soldering.” Moreover, he adds, “Prototype systems resulting from such tiny platforms look neat (without any dangling wires or shabby solder joints) from a demonstration as well as marketing standpoint, surely something that would be very attractive to angel investors or venture capitalists.”

Gupta believes that it helps a designer to innovate and develop products without thinking about the back-end or the support systems. He says, “These latest functionalities in MCUs allow a designer to check the performance of the battery and exactly know where it lags (if it does). This ensures good-quality battery and also a longer life cycle.”

In the Future

“From a system developer standpoint, I would definitely like to be able to see easy availability of inexpensive and micro or mini sensors to grow the Internet of Things purposefully than by the lure of profits,” says Ganesan. There are a whole lot of challenges the world has that need solving. The Internet of Things potentially has the answers to solving these challenges quite quickly, easily and efficiently. However, for that purposeful kind of growth of IoT solutions to happen, the kind of sensors and their associated technologies required need to be worked on as well.

For example, besides the inexpensive and easy availability of tiny sensors, technologies such as micro electro mechanical systems (MEMS), which enable embedding these tiny sensors and/or mechanical parts right on the MCU boards, have to develop and evolve as well, shares Ganesan. He says, “More importantly, the world also needs lots of standards in terms of protocols for handling the various kinds of wireless connectivity that will be in use for communication, the various means of data encryption, storage and retrieval mechanisms.” He adds, “These will be required for ensuring everybody is on the same page and the various kinds of security gateways that will be required for ensuring privacy are not infringed upon, or data leaks do not happen by accident or design.”