This article is based on a panel discussion that happened on the 13th of January at India Electronics Week 2016.

| Panel Discussion: Navigating the Hardware Startup Journey Moderator: Satish Mugulavalli, Co-founder & CEO of RevvX Panellists: Anand Madanagopal, Founder and CEO, Cardiac Design Labs Mohammed Hussain Naseem, Founder & CEO – 2mpower Health Management Services Pvt. Ltd. Madhu Reddy Salla, Founder, Klickh Home Automation & Aizyc Semiconductor Nikhil Kumar, Senior Marketing Manager, Puma |

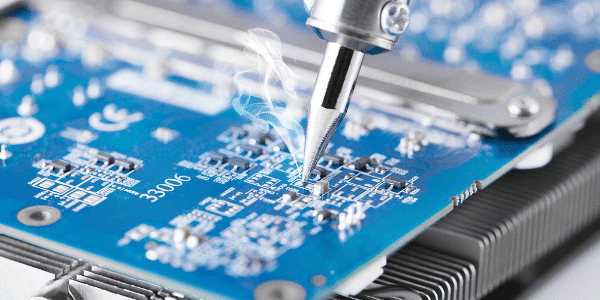

Software startups are everywhere – startups that design apps for almost every imaginable purpose or startups that provide analytic solutions to your company. But there aren’t as many hardware startups. Hardware manufacturing companies face an entirely new set of challenges compared to software ones. Unlike software bugs, it is not possible to correct a hardware mistake easily during the actual manufacturing process – implementing any small change in the design will take a minimum of 6 months time. Since the entire design process of a product takes time, by the time the final product is launched, the market requirements have already evolved. So, the product designers need to think ahead of time to make sure that their design is not outdated at the time of release.

The origin of hardware startups

Hardware startups generally originate due to a certain requirement. For example, the home automation company, Klickh Home Automation, was started when one of the founders was looking at automation options from foreign companies, which were too expensive. Some of the home automation solutions cost about seven to eight lakh rupees – so he decided to tap into this market and try to provide solutions at a more affordable rate. Home automation today does not refer solely to the control of lights and fans – it has evolved to provide more control over the components in a house. This includes getting notifications from the fire alarm, burglar alarm, checking details about the power consumption, as well as keeping track of which family members are present in the house – a very helpful tool for working parents to monitor when their children return from school.

Improving healthcare, with better hardware

Healthcare facilities have also improved thanks to developments in the hardware sector. Consider the field of cardiology, for example – in India alone, the number of cardiac patients is approximately six crores. However, only about five lakh patients undergo surgery for treatment. This is mainly due to the fact that the diagnostic process involves a resting ECG (electrocardiogram), which doesn’t diagnose many cardiac ailments due to the fact that it performs a test on the patient for only ten to 12 seconds. Cardiac Design Labs, from Bengaluru, aimed to take care of this problem by designing an ambulatory ECG that is the world’s first cardiac diagnostic tool on a tablet. It is strapped onto the patient and compiles the results, which can be remotely accessed by a cardiologist. It has been designed specifically with network restrictions in mind – it works well on a 2G network as well.

The OEM challenge

In terms of the manufacturing process, some of the hardware startups choose to work with OEMs (original equipment manufacturers) rather than setting up a fabrication plant of their own. OEMs are solely in charge of manufacturing the components. The company’s intellectual property consists of the algorithms that analyse and interpret the data that is being collected from the devices. The fitness wearable startup, GetActive, follows this approach. Their hardware is manufactured by an OEM, but they handle the algorithms as well as the front-end and back-end software themselves.

The issue of manufacturing quality sometimes leads to problems between the start-up and the OEM. Sometimes the hardware may have some defects, or the OEMs may not meet the required deadlines. A few start-ups prefer to go to China for the manufacturing process. For example, Cardiac Design Labs found that in India, it was too challenging to manufacture a particular type of ECG cable. Instead, they sourced the cables from China. OEMs may also resort to using cheaper alternatives for components which reduces the quality of the product.

Creating the right environment for hardware innovators

The problem that India is facing is that there are a lack of role models in terms of hardware startups. They are ways to overcome this – many institutions now have do-it-yourself (DIY) centres to encourage their students to start building hardware products from an early stage itself. There are also Makerspaces which provide an environment for hardware innovators to meet and network with like-minded people.