Kiran Nataraj, Founder and CEO at Entrib Technologies is an Entrepreneur who is passionate about problem solving. From the Year 2010 Entrib Technologies is on a mission to increase productivity on manufacturing shop floors and add tremendous value to the “Industrial Internet Of Things”.

Q 4th industry revolution; is it IoT or is it just the tide of time in ShopWorx perspective?

A It is definitely here – call it 4th Industry Revolution – Smart Manufacturing – Digital Manufacturing. It is digital technology led innovation that is coming in at a price point that cannot be ignored – it is a do or die for at least the manufacturing industry. This is more so in India because things are easier to do when there is a digital perspective – given the dependency on labour, increased cost of labour, etc.4

Q How are things changing in the IoT industry?

A Things are now being driven more from a use case perspective. While technology is enabling all sorts of use cases – people have to figure out what use cases will bring in the money.

Clearly there are 4 kinds of people in this space – Software Platform providers, Hardware Platform Providers, Service Providers (traditional) and Solution Providers. Ultimately there will only be two kinds of players left – Platform Providers and Solution Providers.

Q What’s new from ShopWorx for IoT?

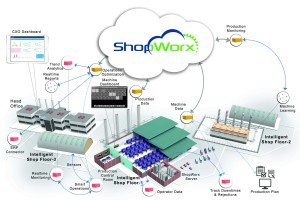

A We have been using ShopWorx to create a digital monitoring and analytics platform for all our manufacturing customers. Now we are focused on taking this to the next level by introducing advanced features like cognitive alerts – making sure possible issues are identified before hand and also getting the information to the right people at the right time – from the Manufacturing Shop Floor to the CxO.

We’re also focused on solving the problem of device discovery in Industrial IoT. Lack of standardization causes deployment times to be longer – in some cases we have to convert protocols to standard protocols by using commercial gateways – that increases the cost of the solution as well.

Q What are the kind of challenges and opportunities being created by IoT?

The biggest challenge is related to lack of standardization – especially for Industrial IoT. This is also an opportunity for startups to disrupt this by providing solutions that can scale faster horizontally.

Another challenge is putting out use cases that actually people (read customers) are willing to pay for. As Jerry Maguire said “Show me the money…”

One more challenge is the availability of hardware platforms for building solutions. While these are good for prototyping and proof of concept – one will have to design their own hardware from ground up – in order to productize the offering. That is still very difficult to do in India.

Q How will this impact developers and designers creating IoT products?

Developers will have to place bets on what use cases will allow them to scale. They also have to choose the correct hardware platforms – ensuring that support for these platforms will continue. Reliance on any one thing will be making or break for their business model.

Q Application areas where this offering can be implemented and enhance customer experience?

We are focused on the Manufacturing Shop Floor, where we are slowly disrupting how data is looked at. In case of Indian customers – the first things are doing is digitizing their production log.

Q How Cognitive analytics contribute to this Zone? If so how?

As far as India is concerned – we are still very much at a basic data acquisition and digitization phase. Basic Analytics (real time) are being now looked at to take decisions faster. Cognitive Analytics will start playing a key role once there is enough data to be able to run such analytics and provide solutions in the area of predicting failure or quality of goods produced. Our approach is to get into Cognitive Alerting as a first step in this journey.

Q What specific benchmarks – metrics would your systems look at in order to reduce rejections in a manufacturing plant? Could you please quote a real time example?

There is a very interesting use case that we have now implemented in one of the largest 2 wheeler manufacturing company. On one shop floor there are more than 160 spot welding guns. We are running real time analytics on all the guns to measure the quality of the weld. We are doing this by putting in sensors to 6 data points for each gun– and in this case if any of the parameters are not within defined set – there is real time feedback that does not allow the operator to proceed. Data being analyzed is at the rate of more than 12000 records per minute – all the data collated is looked at along with other data across the shop floor – in real time – to take a decision on whether the whole part is welded properly – giving rise to zero rejections in a very much manual process! Doing this with earlier technologies would be mind boggling – not to mention that it would not be real time. Everything would have to happen discretely (within the gun itself) – and managing it would be a nightmare. Not the entire thing can be looked at in software and controlled in software! The next thing is to look at predicting failures in the field – integrating with data coming from the field – that will be the true power of IoT.

Q Other unexplored domains ShopWorx can be implemented and create a “Buzz” according to you?

ShopWorx being a platform at its core – can be applied across multiple domains – limited only by now where we can sell and what use cases will give us most “bang for the buck”. Our focus is and will continue to be in Manufacturing – vertical by vertical.

Q Can ShopWorx venture into hyper-local delivery and increase delivery efficiency?

In its earlier Avatar – ShopWorx had a couple of use cases for delivery tracking and a couple of paying customers as well. But that sector is going through a whole lot of turmoil – and in our opinion it is not a good sector to sell into currently – given that most of the prospects will be other startups!