There was a catastrophic incidence of oil spillage from the oil rigs in Gulf of Mexico in April 2010. The drilling rig ‘Deepwater Horizon’ had spilled about 185 million gallons of oil into the sea, endangering breeds of marine creatures. Later, forensic reports proved that a puncture in the pipe due to oil and gas pressure had created the havoc. Had there been a smart automation system in place, the fault would have been detected at an early stage, hence avoiding the mishap.

This incident highlights the necessity of smart automation in industries. And as it is said “necessity is the mother of disruption,” the dire need of a safe, secure and efficient industrial system gave birth to the Industrial Internet of Things or IIoT.

The IIoT roadmap

There was a time in the 18th century when industrial machines were powered by steam. Industry 2.0 was powered by electric energy and industry 3.0 went autonomous. Now we have industry 4.0, which runs on cyber-physical systems.

This paradigm shift of the industry norms from manual to smart automation is helping to remotely monitor and control every part of the industrial facility.

“Later, five considerations were taken for enabling IIoT—distributed intelligence, rapid connectivity, establishing open standards and systems, real-time context integration and autonomous production lines,” says Narendra Sivalenka, senior manager-IoT team, Cyient.

Extracting data from all systems or extricating data from the main system and placing it into different machines in perfection is the distributed intelligence in the IIoT. This data is then connected with each other in a network after integration. Later, as per customer needs, this data is extracted in a smart way to avoid monotony of work, maximise throughput and minimise labour cost.

Technology behind the IIoT

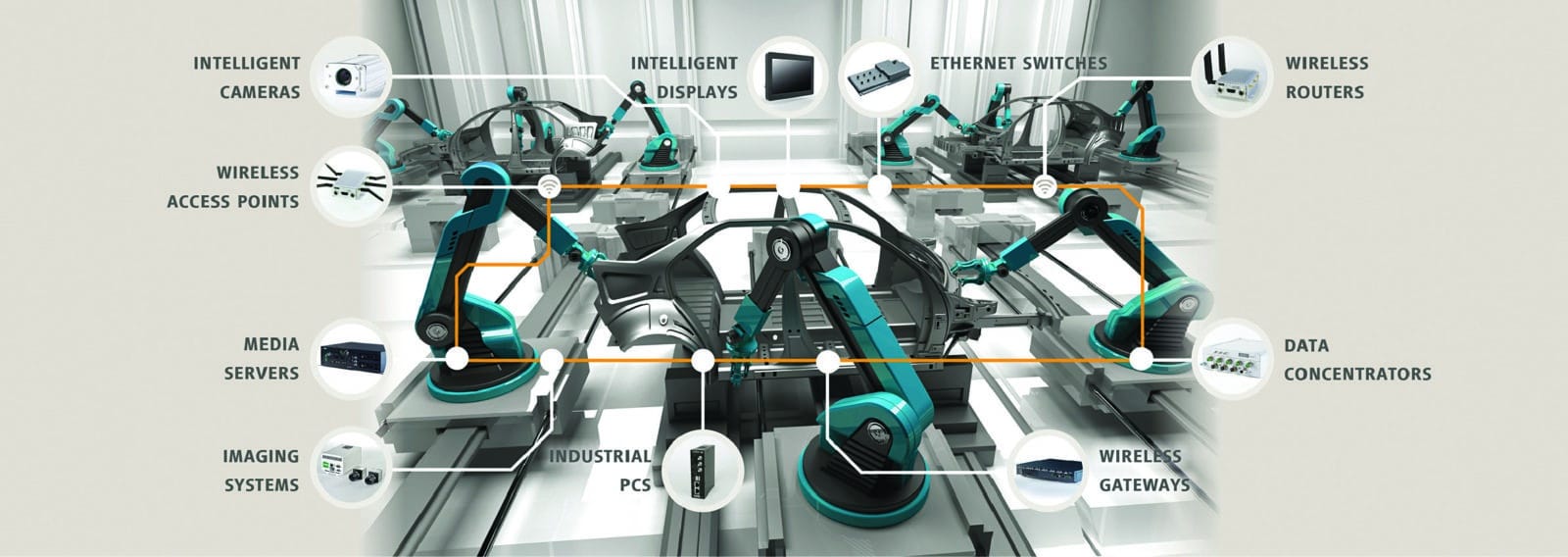

Hardware components of the IIoT include sensors, RFID, condition monitoring, distributed control systems (DCS), smart meters, camera system, industrial robotics, AHS and networking technologies. Product lifecycle management (PLM) systems, manufacturing execution systems (MES) and supervisory control and data acquisition systems (SCADA) are the software parts.

Processor technology, artificial intelligence, DRAMs and memories, and virtual and augmented reality are fields of the IIoT where something exciting is happening on a regular basis.

Driving circuit

As mentioned in ‘Industrial Developer Boards’ article of July issue, these boards are undergoing a complete technology change. These find various IIoT applications including robotics, automotive manufacturing, power grids and many more.

The RF-based detector in industrial developer boards allows 3D mapping of objects using time-of-flight concept. Thus, antennae are embedded in the system itself, making the board condensed while reducing processing time. Such industrial developer boards are beneficial for robotics.

Footprint reduction of FPGAs, antennae and other critical components is creating a boom in the industrial IoT segment. Reducing the component size not only helps in reducing the manufacturing costs but also in thermal suppression. Be it the power supply section for a developer board serving the pick-and-place machine or a developer board for smart lighting, thermal dissipation is considerably low.

For applications like motor drives, machine-to-machine communication and smart grids, real-time processing and analysis, longevity, warranty and flexibility are key factors that make industrial boards the preferred option over normal boards. Typically, these can withstand industrial temperatures ranging from –40 degrees to 80 degrees centigrade. There are also a few developer boards meant for ovens, which can withstand temperatures of more than 300ºC.

Sensor integration allows a device to perform several functions. For instance, automobiles are now well-equipped with Bluetooth, Wi-Fi, indicators, odometer, fuel indicator, theft alarm and many such features.

Similarly, infotainment system, cluster, automotive and automotive advanced driver assistance are now integrated on a single MCU, thus reducing the wire harnessing and simplifying the anatomy of cars, making them safer as well as far more efficient.

In these cases, developer boards are designed to integrate a number of functions, which helps to reduce the design costs and space requirements.

Smart camera and imaging system

Similarly, imaging is no longer restricted to laboratories only. It is now gaining significance at the industrial level as well.

A leading automobile manufacturing company employed a robotic arm for automation, which was used to detect the objects to pick and assemble only at a spatial frame and angle. But, even if there was no work, the robotic arm continued to move, which reduced its service life and wasted electricity.

Now, with smart automation, robots can easily identify objects in 3D space too. This is particularly helpful for the automation segment, where robot arms could identify the objects to be picked and placed in a single direction only. Thus, 3D vision is making manufacturing smarter, saving time, electricity and human efforts.

New measuring techniques have come up for the automotive industry’s paint lines, which combine deflection in 3D and 2D surface inspection. This technology in cameras controls the quality 100 per cent and the inbuilt sensors deliver precise automated results in real time.