As of now in this article series, we talked about the limitations imposed by primary batteries while designing IoT applications, BLE device states and how to optimize each of them to work well with the primary batteries. We also discussed other subsystems that impact total and peak power consumption and how to optimize them.

In this part, we will discuss how to manage high internal resistance of coin-cell batteries to improve effective capacity, precautions to be taken while measuring battery voltage and power estimation.

Managing high internal resistance(IR) of coin-cell batteries

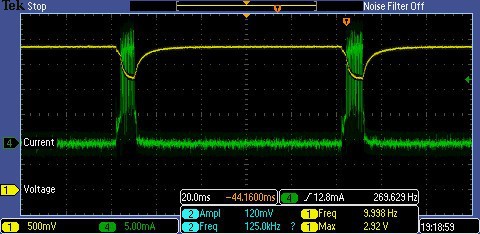

To recap from the part 1 of this series, coin-cells are being preferred in space constraint applications that need to transfer few bytes of data at regular intervals for example beacons or wireless sensor nodes. However, coin-cell batteries do not perform well when load current starts going beyond few 100s of uA. Battery capacity starts degrading with an increase in the load current. Also, battery voltage starts dropping quickly due to increase in internal resistance when high load current is drawn continuously and battery’s internal resistance starts increasing as battery capacity gets utilized. Figure 1 shows the scope capture of load current and battery output voltage for a sample BLE application.

Figure 1: BLE device load current (green) vesues battery output voltage (yellow)

Usable capacity of any battery in a system depends upon the minimum operating voltage of the system. That’s why internal resistance of battery plays an important role in determining the effective capacity of battery for a given system.

To tackle this high internal resistance, a capacitor can be added in parallel to the battery output. This capacitor acts as source for high peak current while maintaining the required voltage. This capacitor needs to have low-ESR (equivanant series resistance) so that when load is applied, output voltage does not drop significantly. A ceramic or tantalum capacitor can be used for this purpose as they have low ESR and low leakage. It is very important to choose a capacitor with low leakage otherwise a significant battery capacity will be consumed by capacitor itself. Value of capacitor can be calculated based on the unloaded battery voltage, minimum operating voltage of the system, peak current, peak duration and low-power time. Capacitor should be able to hold enough charge to supply high peak current while maintaining voltage above the minimum operating voltage of the system. Equation 1 can help finding the capacitor size needed to hold required charge.

C = I x Δt / ΔV – (Equation 1)

Where, C is the capacitor size in Farads, I is the current amplitude in Ampere, Δt is the time in seconds for which current is drawn (if there is 10 mA current drawn for 5 ms and 12 mA current drawn for 10 ms, I x Δt will be – (10 mA x 5 ms + 12 mA x 10 ms)/106, ΔV is the differance between unloaded voltage and minimum required voltage (in volt) for the system. For example, if unloaded voltage is 2.5V at a120mAh battery utlisation and minimum operating voltage for system is 1.8V then ΔV would be 0.7V.

There must be sufficient time for capacitor to charge before next current peak otherwise capacitor voltage will drop below the required voltage and device may get reset. So, system designers must ensure long sleep/low-power intervals after peak current draw.

Though adding capacitor can be useful in some applications, it may yield negative results in some applications. For example, if a sensor node needs to transmit one packet every minute and uses a capacitor with 2 uA leakage, will bring down battery’s life.

Battery voltage measurement

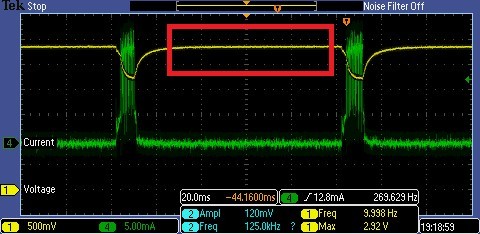

In most applications that run on coin cell batteries, voltage measurement is done to let the peer or local device know the battery voltage level. For low capacity batteries, the voltage level of the battery can drop significantly during the RF transmissions due to sudden surge of high peak currents and once RF transactions are completed, it needs some time to settle down to the original voltage level. So, battery measurement shall be scheduled after battery voltage level has settled, or before device starts transmitting or listening in given interval (refer the red box in the Figure 2).

Figure 2: Scheduling Battery voltage measurement

Figure 2: Scheduling Battery voltage measurement

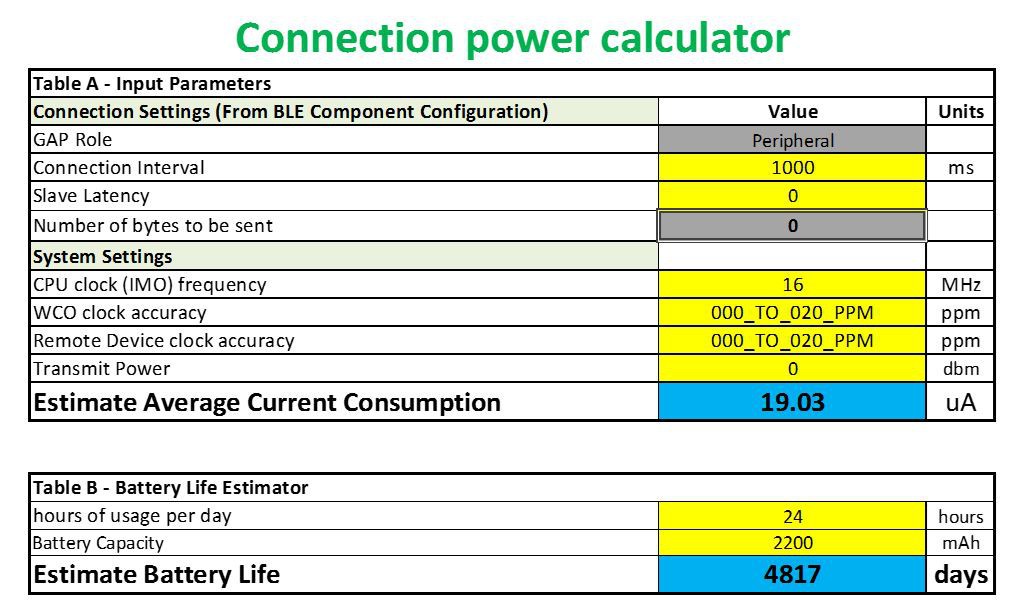

Battery life estimation

Estimating battery life for IoT applications can be tricky as current consumption depends on various parameters like Rx and Tx current, leakage current, power consumption in different power modes, current consumption during transition from one power mode to another, clock accuracy etc. Some silicon vendors provide battery life estimator that helps estimate battery life. In early stage of product development, these calculators can help understanding impact of change in various parameters like clock accuracy, interval etc. on average power consumption. Based on the same, component selection and other BLE parameters can be tweaked to reduce average power consumption. For example, Figure 3 shows the screenshot of the battery estimation tool from Cypress Semiconductor for its PSoC 4 BLE devices. As shown here, this estimator will help estimating battery life for a peripheral device based on connection interval, slave latency, CPU frequency, clock accuracy, transmit power, hours of usage per day and battery capacity. If estimator is not available for a given device, a crude estimation can be done based on the parameters provided in the datasheet and application requirements.

Figure 3: Battery life estimation for a BLE device

Conclusion

A capacitor can be connected in parallel with battery to tackle high internal resistance. Capacitor size depends upon load current and minimum operating voltage. Capacitor shall be picked carefully to ensure low-leakage. Battery voltage shall be measured before voltage drops due to loading. Power estimation tools can help estimating battery life in the initial stage of product life cycle and help tweak various parameters to achieve optimal power consumption.

In upcoming parts of this series, we will discuss how energy harvesting devices can help increasing battery life in IoT devices.