A good battery gives an electric vehicle the power to traverse long distances without any tension. But when upgraded with next-gen technology such as IoT and AI the the entire system is bound to become even more enhanced.

Battery management system (BMS) is a crucial part of an electric or autonomous vehicle. But what has the Internet of Things (IoT) or artificial intelligence (AI) got to do with the battery? Let’s see.

The term IoT, coined in 1999, refers to the interconnection of sensors and software on a network. It helps control the connected devices, and their relevant data can be collected and visualised with the help of a user interface.

The main functions of IoT are:

- Collect. Gather data from sensors and various other devices in a home, vehicle, or manufacturing plant.

- Communication. Send the data to a destination such as cloud, AWS, Azue, or a personal data centre using a communication gateway through Wi-Fi, 4G, or 5G, etc.

- Analysis. Collect useful information from the raw data to visualise, generate reports, and to make predictions.

- Action. Based on the analysis, communicate with other devices through machine-to-machine (M2M) protocols, or send notifications (SMS, email, etc) to the concerned persons for rectifying any errors.

Most people think that cars such as Tesla’s Model S only can be classified as EVs. But that’s not the case. We have had EVs in India for a long time, such as electric trains which are also EVs. Their engines are traction motor based. The central part of an EV can be a traction motor, a BLDC motor, or an AC induction motor.

EVs are catching attention because of their advantages such as:

- Much lesser dependency on petrol, diesel, or other fossil fuels

- Ensuring environment is free from pollution and noise

- Come with recyclable lithium-ion (Li-ion) batteries

- Low maintenance and low operation cost

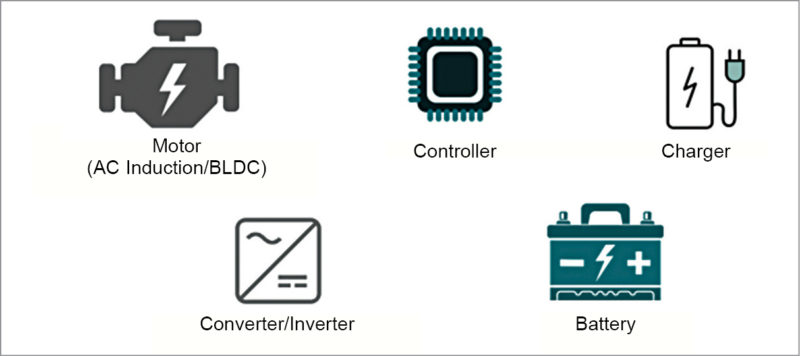

The essential components of an EV include (see Fig. 2):

Motor

It can be an AC induction motor or a brushless DC (BLDC) motor. Although there is a massive debate raging on which one is the best, they both have their advantages and disadvantages. Different companies use different types of motors. For instance, Toyota uses AC induction motors, whereas Volkswagen prefers BLDC motors. Tesla Model S has an AC induction motor while Tesla Model 3 has a BLDC motor.

Controller

It is an electronic module that controls everything in a car—from the power deliverance of a battery to the power requirements of a motor.

Charger

There are two types of chargers. One is like a travel charger that can be plugged into a household electrical socket; this charger is generally slow. The other is the super-fast DC public chargers that are setup on the highways, fueling stations, or motels, etc.

Converter/Inverter

It can be DC-DC or DC-AC, depending upon the type of motor used (AC or DC).

Battery

Li-ion or Li-po (lithium-polymer) batteries are generally used in EVs due to their low maintenance and high power delivery characteristics.

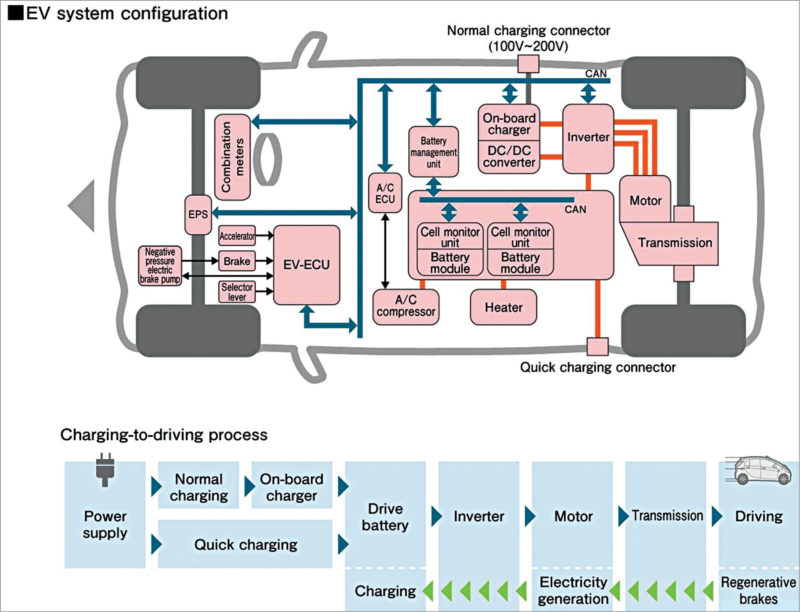

EV system configuration

EV batteries are charged either through onboard chargers built within the cars from AC grid, or through fast chargers available at public charging stations. Onboard charging takes 7-8 hours to charge from 0% to 100%. But fast chargers installed in petrol pumps or highways can charge from 0% to 100% within 1-3 hours.

After the battery is charged, an inverter converts DC to AC or DC to DC depending on the voltage or current required by the motor.

There are regenerative brakes in most EVs, which generate electricity whenever brakes are applied and charge the batteries while driving.

The transmission consists of a gearbox and related components.

Most EVs have batteries in the car’s base (due to safety reasons) instead of the boot or the front. If anything goes wrong with the battery, or it blasts, the car and the drivers will be safe. This is where battery management system (BMS) plays a critical role.

BMS with IoT & IoT

Now let us see the role of BMS in an EV, that is, how by integrating IoT and AI in BMS, we achieve another technological advancement.

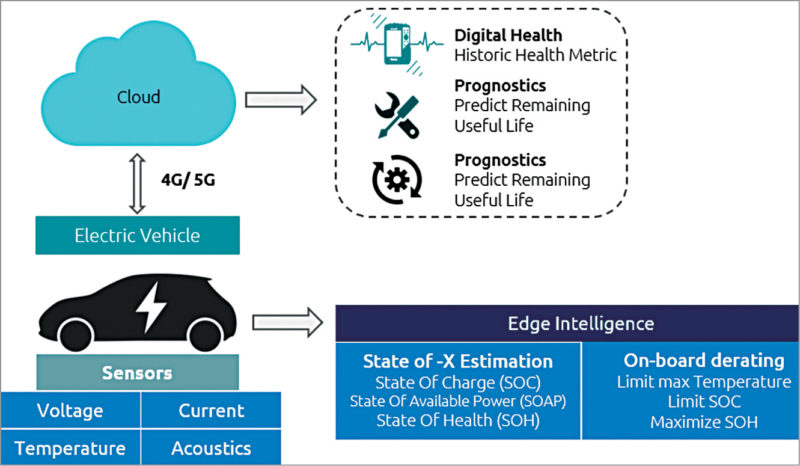

Fig. 4 shows how typical integration of BMS with IoT and AI looks like. The multiple sensors are installed in the BMS of an EV to monitor voltage, current, temperature, and acoustics/vibration. These parameters are collected every split second. In intelligent vehicles and EVs, an edge intelligence system is used, which reduces dependence on the cloud.

Most EVs have embedded computing systems that work in real time to do the basic operations automatically, such as the State of X-Estimation—where X stands for State Of Charge (SOC), State of Available Power (SOAP), and the State Of Health (SOH).

The actions taken by edge intelligence can help limit certain anomalies such as the maximum temperature by lowering the power consumption by the motor. Although this can make the EV slightly slower, the motor won’t draw excessive power and overheat the battery. Edge intelligence can also control the State of Charge to maximise the State Of Health.

With the help of 4G/5G, the data can be sent to the cloud. Graphic processing units (GPUs) with huge computing power can calculate digital health and predict the remaining useful life on the cloud. If an anomaly occurs in the BMS, a notification is sent to the registered mobile phone or on any dashboard application installed in the EV.

Basically, a digital twin of an EV and every part of it (such as a battery, motor, controller) is created. And data from different sensors are analysed to deliver the safety of the driver, passenger, and the vehicle itself.

Some benefits of integrating BMS with IoT are:

- A mirror framework (digital twin) of processes and functions of a car is created on the cloud or edge

- Sends updates and maintenance notifications from the car to the maintenance engineers, or the car owner/company, so that they can guide for any servicing requirements

- Initiates system warning in case of any anomaly

- Management of energy stored in a battery and the amount of charge required (smart charging)

- SOX estimation

- Battery diagnostics

- Cell balancing

- Data collection and processing

Big car companies like Tesla and MG have already installed different kinds of sensors in their cars. So, on swapping a battery, you receive a notification that the battery has been uninstalled/installed in a vehicle. Also, these batteries come with an electronic control unit (ECU), which has its digital properties and identity.

On the topic of data privacy, it does not matter which company provides the battery. Generally, the data-sharing policies of a car manufacturer play a decisive role. When a car company shares data with the battery manufacturer, the latter can optimise battery production according to the requirement and save a lot of time and cost.

The article is based on the talk ‘The Combination of BMS and IoT In EVs’ by Arqum Ahmad, Scientist (Digitial Twin) at Leonardo S.p.A, Italy, presented at February edition of Tech World Congress 2021. He is also the co-founder and former CEO of Antrax Labs, India. The article is compiled by Vinay Prabhakar Minj, a technology journalist at EFY.