- Monitoring system with an enhanced self-regulating property for more precise notifications in real-time.

- Brings with itself a host of features for effective predictive maintenance that reduces downtime and increases the production capacity.

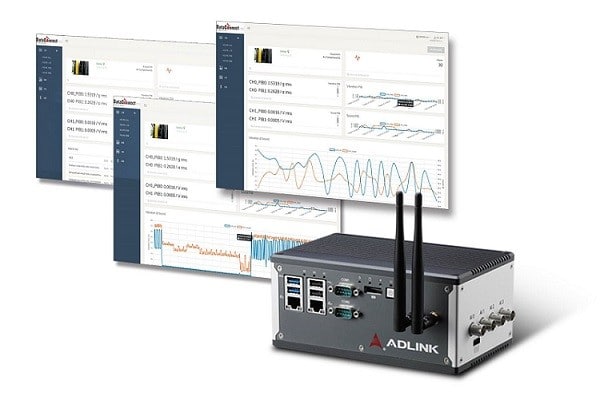

ADLINK Technology, a global provider of leading-edge computing solutions, has launched the DataConnect Pro Remote Facility Information Dashboard, an upgrade to its MCM (Machine Condition Monitoring) solution.

The dashboard is built to work on the edge platform and comprises of an integrated sensor management structure for a detailed data acquisition and clear-cut vibration analysis. This, in turn, allows users to simultaneously monitor multiple system devices while performing machine operation.

Tim Juan, Chief Director, Smart Factory Business Center – ADLINK says that manufacturers who have actively established automated monitoring systems can often end up suffering due to a large number of invested resources, lack of software developers and system integration capabilities, and difficulty in assessing benefits.

He adds that through this upgrade, it is aimed to help enterprises build smart device monitoring applications right from the end (device, sensor, gateway) device to cloud (PaaS (Platform as a Service), SaaS (Software as a Service)). This step will lead to more effective equipment failure prevention.

Reliable and convenient

Based on the powerful Microsoft Azure cloud platform architecture with no need for any additional program development or architecture modification, the solution can be easily deployed in multiple fields.

Advantages

- Reduced cabling complexity and cost, alongwith minimal footprint allows quick and easy installation in proximity to the monitored equipment.

- Well defined predictive alerts on equipment abnormalities that prevent unexpected breakdowns and costly downtime.