I have been working with startups especially the ones which are into electronics for the last 4 years and currently helping 3 startups which are developing products based on the research work done by the promoters.

By Srinivasa Moorthy S A

Each one of them is in a different area but the common thread is the research they have done is path-breaking and completely new with great market potential. However, what I have seen in the last year working with them are the challenges and issues that these companies are facing. I want to highlight some of them for anyone who is getting into this type of research-based product development.

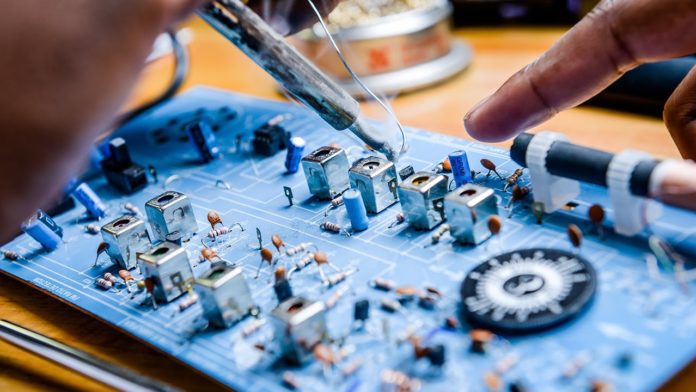

First, let us remember any research-based product is very abstract to begin with and the product development calls for skills which are basic. Designing and taking them to manufacturing is a big challenge as the skills and infrastructure needed practically don’t exist.

All three startups have mechanical components and mechatronics components in the design. However, we hardly have designers who can do design from basics. For example one of the startups is designing a product where a motor has to be synchronised to an already rotating element at 6000 RPM and above and I have not met anyone who knows how this can be done. Fortunately, the kids who are running the startup have found out how to do this after a lot of hard work!

Similarly, one of the startups which is into educational tool development for specially-abled children had difficulty in designing parts with aluminium. In fact, the issue was sorted out by a designer who has no graduation in engineering but a hands-on guy who designed the components based on our inputs. The irony is, one of the Engineering R&D Service companies which volunteered to help keep on telling the team why this will not work (I advised them to stop listening to this company)

Next challenge is manufacturing, one of the designs has multiple plastic parts and we decided that we will use 3D printed parts. After speaking to multiple vendors who can “do 3D Printing” we realised none of them either have knowledge of plastics nor they have exposure to designing for 3D printing. Currently, the team is solving this problem on their own.

The end result of the design skill gap and manufacturing skill gap is, the startups are spending lots of time on these issues (which they thought the vendors will do) which is not budgeted and leading to delay and excess time and money being spent.

Based on my experience my advise to startups with these type of products are;

- Assume every piece of work has to be done by you and plan for the same

- Spend good time in understanding the materials used, manufacturing technology and the process associated with that.

- Identify likely partners before starting your work and evaluate them before you engage them (I have seen too many self proclaimed experts who will be advising you without any knowledge)

- If you have moving parts in your design be very careful and get your physic right!

- Above all plan for delays as these can turn in the opposite direction than what you had planned

| Srinivasa Moorthy S A is the Chief Executive Officer of the Andhra Pradesh Electronics & IT Agency. He has over 30 years of experience in the IT industry as Head, Leader & Technocrat in the Electronic Product Design & Engineering Services. |