Nowadays most electronic devices are being designed with a touch of the Internet of Things (IoT). Test and measurement (T&M) plays a big role in successful mass-deployment of the IoT. Expanding applications and newer protocols require T&M devices for IoT applications to upgrade simultaneously. What are these upgrades and how are they changing the paradigm of T&M for the IoT? This article answers such questions.

Testing an IoT system

Optimal testing of an IoT system depends on how its intricate components are tested and measured. The IoT encompasses different wireless technologies like Wi-Fi, Bluetooth, cellular (2G, 3G, LTE and narrow-band IoT), Zigbee, LoRa and so on. It draws strength from the level of connectivity these technologies provide.

Mombasawala Mohmedsaeed, general manager (applications), Keysight Technologies India, explains, “Test gears are available to measure the functioning of these technologies overall. However, the importance lies in having a low-cost T&M solution for testing the individual IoT devices involved in these technologies. The devices themselves are low-value instruments capable of connecting to the network and sending or receiving commands.”

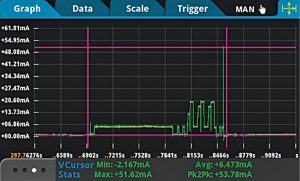

So what are the essential layers that an engineer needs to test in order to ensure an efficient IoT system? Mombasawala answers, “Engineers mainly look at transmitter and receiver measurements, which are radio-frequency (RF)-based. Depending upon the chosen wireless technology, manufacturers perform tests like spectral emission measurement, channel bandwidth measurement, receiver sensitivity measurement and so on. All these measurements of an RF reading device are based on power, frequency and bandwidth. Another critical measurement required in the IoT is battery drain analysis. There are certain test gears in which the current and voltage cycles can be varied and one can bleed out the battery to test how long it can support a real-time application and how long it lasts (battery life). With the right chipset, a strong battery and the small unit of a transceiver, the IoT device is ready to connect to the network.”

T&M devices

Test equipment manufacturers focus on setting up appropriate firmware to support the different IoT bandwidths and frequencies. They are removing the redundant hardware from test devices and bringing down the cost of test devices in proportion to the scale of design.

Mombasawala talks about Keysight’s equipment roster as an example, “IoT chipset designers need a full-blown testing system that will support 2G, 3G, 4G and higher technologies. UXM of Keysight is such a device. However, options like this are expensive. Many developers who are creating a new RF system may look for something more economical. Moderate systems that measure frequencies below 6GHz are available for the purpose. Instruments like signal generators are used to generate signals and test the receiver of the IoT. Signal analyzers take signals from the IoT transmitter and analyze these. All these come as handheld devices. These can be used by manufacturers as well as R&D departments.”

Testing the battery capacity and power consumption of an IoT system is the third major criteria. Mombasawala continues, “We also have battery drain analyzers. Battery drain testing is generally done at R&D stage and requires a voltage-current measurement setup.”

Test device upgrades

T&M providers are trimming the tests supported by their equipment down to the transmitter, receiver and power-based measurements. They are making the test devices more modular. The port density is increasing. Newer test devices support higher number of parallel devices under test (DUT) and improved test capacities at economical rates. This is making the T&M device hardware futureproof.

Typically, IoT systems are made up of at least one sensor, a microprocessor and an RF chip. The system draws and releases current of varying magnitudes in different states. So the optimal test equipment should come with dynamic current sensitivity ranges. These should also support sufficient bandwidth for proper signal sampling. Test equipment for IoT systems are being modified accordingly. Firmware and software upgrades, hardware miniaturization and capacity improvements are some other trends.

T&M players like Anritsu and Litepoint have rolled out new hardware for test devices intended for use in manufacturing floors. The modification included removing some redundant features in the existing systems originally meant for R&D purpose.

Mombasawala iterates, “We removed the capability of protocol testing, which initially was to do the communication test and see how the system connected to the network. This is usually verified separately during R&D. So it is not required to be tested during manufacturing.”

Here are a couple of upgrade examples. E6640A EXM wireless test set by Keysight has been upgraded to support 32 DUTs using multiport adaptor technology. It can measure up to 6GHz bandwidth. The upgrade enables the setup to complete testing of one IoT device within 27 seconds, compared to earlier iterations that took 40 seconds.

Tektronix RSA306B USB spectrum analyser is capable of real-time RF detection and troubleshooting. Battery drain analysers are becoming touchscreen and featuring a graphical interface. DMM7510 multimeter, for example, has a graphical touchscreen display with high resolution. Talking about upgrades in terms of measurement sensitivity, Keysight’s test setup can give a measurement down to 150 picoamperes. It can also measure the dead current/current leakage when the system is idle.

Softwares are also upgraded regularly to ensure a smooth T&M performance. Mombasawala says, “We have developed certain algorithm for test devices on our Test Automation Platform software. We have done a lot of threading of ports with which we are able to schedule a large number of parallel DUTs. The automation software allows users to switch between ports internally and optimize measurement of the hardware.”

Statistical control is another major upgrade to IoT T&M software. Software with statistical control store various data and statistics based on historical tests, and utilize these to further speed up T&M. This ensures a quicker time-to-market.

Mombasawala explains, “In statistical control, there is a timing analyzer. Suppose 9-10 tests are assigned for a DUT. This feature will analyze statistics of the time required to execute the tests successfully on the connected IoT device. Once analyzed, it can enable smart scheduling of the test and thread it in a manner that the hardware gets further optimized. As a result, we have seen 30 percent reduction in test time.”

Challenges in IoT T&M

Test setups for manufacturing floors differ from those built for R&D labs in terms of cost and efficiency. Mombasawala explains, “The challenge comes from the economical/commercial side. Businesses do not have a large profit margin on IoT test equipment because the IoT itself uses very low-cost devices. So a test device costing around $50,000 will not bring much business. The solution is to plug out all the redundant hardware and keep only the IoT-specific hardware. However, the task is quite difficult and work is mostly under progress. The speed of testing also remains a challenge since commercial production of IoT devices involves bulk quantities. While some new platforms have been rolled out, improvements are still going on.”

Mombasawala suggests buyers to look for scalability, upgradability and serviceability. According to him, “Scalability can be mainly ensured through high port density. The device should have the capability to keep on adding more and more ports and have a variety of modules. Without this, different assembly lines will require a different tester, which will take up a lot of money and space. Upgradability means software and firmware should align to the new standards set by 3GPP. Also, look for a good repair and calibration option offered by the vendor.”

The Future: Ready for 5G?

Among wireless technologies of the future, 5G is garnering the most attention. It will enable M2M communication and involve more IoT technology. However, it remains to be seen which frequencies and bandwidth 5G will align to.

Industry players are already taking a step forward by designing 5G-ready test setups. For instance, Litepoint has released IQgig-5G, which is said to support 28GHz and 39GHz frequencies of the millimetre-wave spectrum, along with other technologies.

Manufacturers are ensuring that their hardware and software designs are already 5G-proof so that they get the first mover’s advantage as soon as 3GPP and other bodies officiate the launch of 5G protocols. It is quite obvious that in the long list of upcoming upgrades and modifications to IoT T&M, 5G support is the one to look out for.

Paromik Chakraborty is a Technical Journalist at EFY